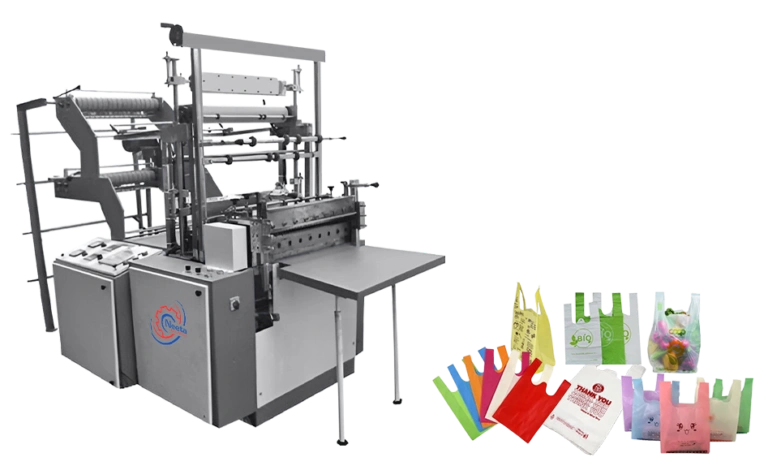

The Fully Automatic Bottom Sealing & Cutting Machine from Neeta Industries is a state-of-the-art solution for producing a wide range of plastic bags. Engineered with precision and efficiency in mind, this machine specializes in bottom sealing and cutting, making it an essential asset for manufacturers in the packaging industry. Designed to handle high-speed operations while maintaining accuracy, this machine ensures secure sealing and clean cuts every time. Built for durability and ease of use, it provides reliable performance with minimal maintenance, making it the perfect choice for small to large-scale production.

Explore the detailed specifications of our Fully Automatic Bottom Sealing & Cutting Machine, designed to ensure superior efficiency and precision in sealing and cutting operations :

| Model | Fully Automatic Double Decker Servo-mech Bottom Sealing & Cutting Machine Sizes |

|---|---|

| Model | NI 800 mm Single Decker , Bottom Sealing & Cutting Machine |

| Machine Type | Bottom Sealing & Cutting |

| Bag Width (mm) | 50 to 800 mm |

| Bag Length (mm) | 50 to 1000 mm |

| Production Speed (cycles/Min) | 200 strokes per minute |

| Material Thickness (microns) | 10–200 |

Discover the wide variety of bags that can be crafted with our advanced machinery :

•T-Shirt Bags • Garbage Bags • Vegetable Bags • Courier Bags • Flat Bags

Looking to upgrade your production process or have specific requirements? Contact Neeta Industries today for a personalized quote. Our team will work with you to understand your needs and recommend the perfect solution. Simply fill out our contact form or reach out via phone or email for more information on pricing and customization options.

WhatsApp us